A gay porn daddy is regularly a more seasoned man, but on the other hand he’s for the most part defensive of his more youthful darlings and can be prevailing and monetarily liberal. For the reasons for our pornography recordings, the daddies are more established and anxious to investigate a large number of sexual joys, from stroking off their developed cocks solo to connecting with folks of any age for oral and butt-centric sex.

Hi-Tech Smart Vibrators

Technology does not stand still, the world is constantly evolving, progress is penetrating into all […]

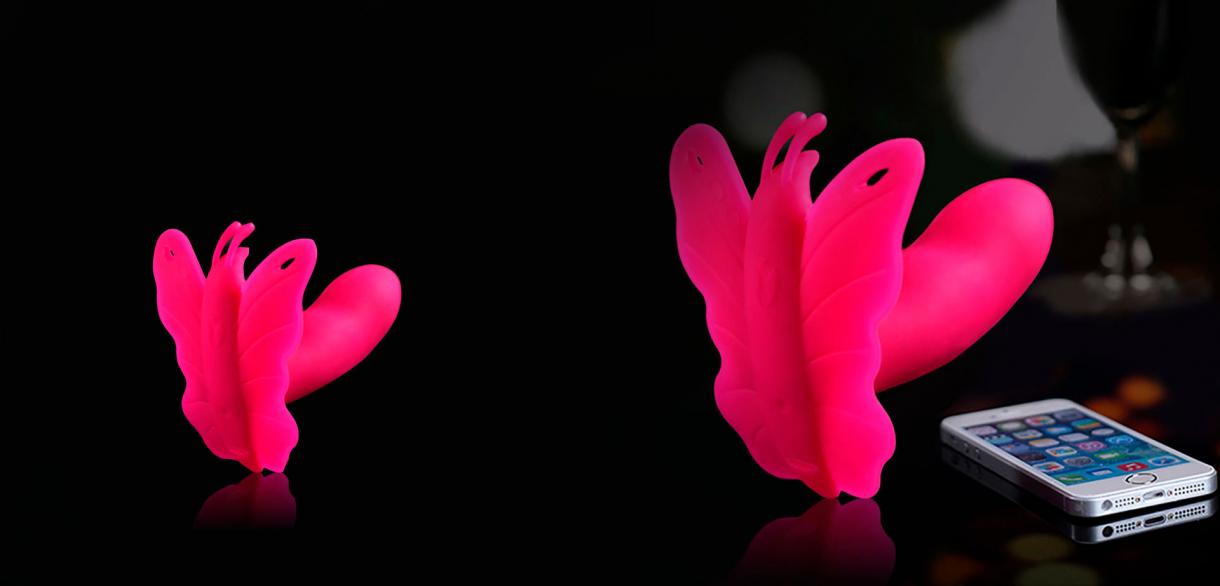

Butterfly vibrators

The process of masturbating the cock while inserting one’s fingers, tongue, or toys into a man’s tight ass is known as prostate shemale massage porn. Due to the location of the g-spot in a man’s ass, many dedicated women work tirelessly to properly massage and cum their partners’ prostates. While they are massaging, you may occasionally get to witness them suck dick; other times, they may be wearing strap-ons.

Vibratory panties

Every woman who has studied her body for a long time knows very well which […]

Vibrating bullet

The number of female orgasms can be anything if you use the right device for […]

Mini vibrators

What is the easiest way for a woman to reach orgasm? To buy a vibrator […]